Renfe, the Spanish state-owned railway company, started to manufacture spare parts for its train fleet using 3D printing technology. To accomplish this, Renfe uses additive manufacturing technology through a collaboration with the Aitiip Technological Center.

Renfe's decision to adopt a comprehensive additive manufacturing service (3D printing) enables the company to produce railway components needed for both new production and spare parts. This service is particularly valuable for manufacturing parts that are either obsolete or damaged.

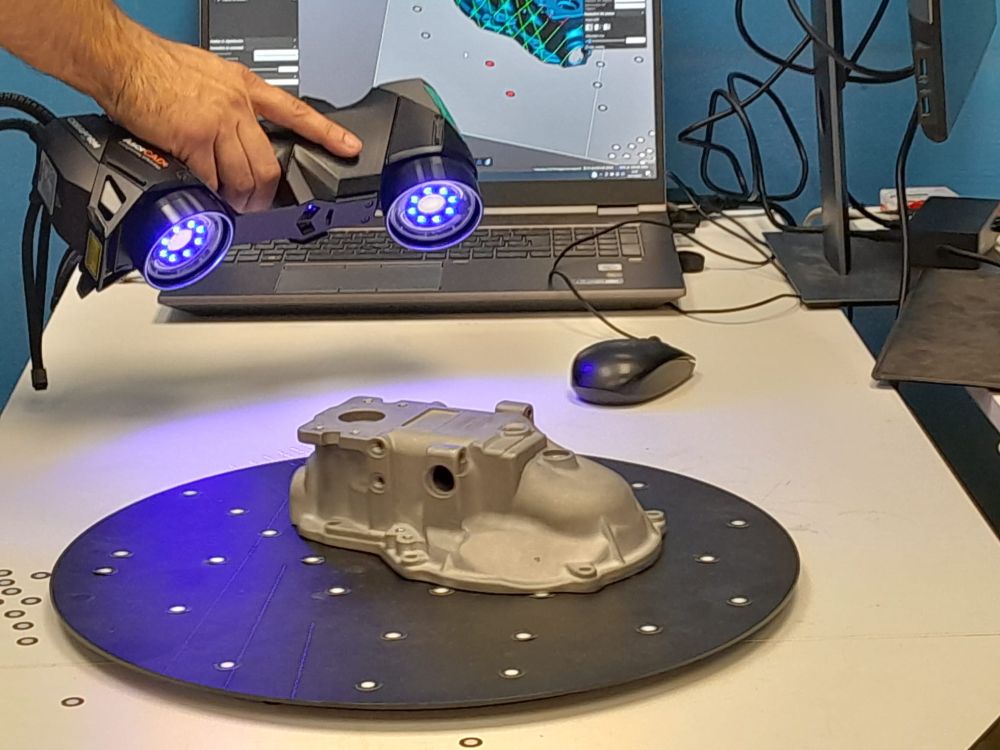

The project's hub, the 3D Printing and Reverse Engineering Pilot Center, is located at the Madrid Comprehensive Maintenance Base in Villaverde. It is staffed by a team comprising Renfe engineers specialized in Reverse Engineering and Aitiip personnel skilled in 3D Printing. This collaborative team is responsible for coordinating and executing work to support Renfe's maintenance centres across Spain.

Aitiip manages the entire manufacturing process, utilizing state-of-the-art machines to print the parts. The collaboration began in early 2023, following Aitiip's successful bid in a tender process initiated by Renfe. The contract between Renfe and Aitiip emphasizes providing agile, precise, and efficient services, optimizing the value chain from identifying a need to fulfilling production.

The 3D printing service includes a comprehensive product value chain, from detecting and analyzing needs to scanning part geometry and 3D digital modelling. This technique allows for redesigning and improving parts before printing them in plastic materials with high mechanical performance, certified for railway use, and in compliance with fire and smoke regulations. Materials like aluminium and steel are also used, depending on the requirements.

Renfe and Aitiip have worked together on designing and manufacturing reinforced parts and tools for different production processes, including prototyping parts for subsequent production using traditional technologies. They have already successfully printed several series of parts, such as ventilation grilles in driver's cabins and regulator covers for diesel engine injection pumps.

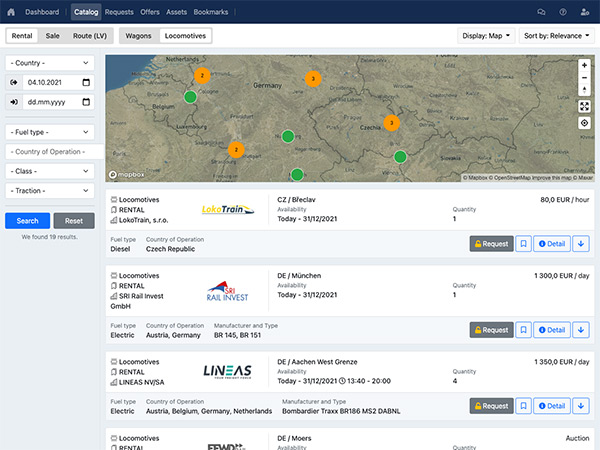

Furthermore, all data collected from the parts becomes part of a 3D digital inventory within the AD2 platform of Addvance 3D, a startup that won the III TrenLab Call, Renfe's open innovation program. This platform aids in precise monitoring of each piece's data, including material type, dimensions, markings, and cost, thus optimizing production times for future needs.