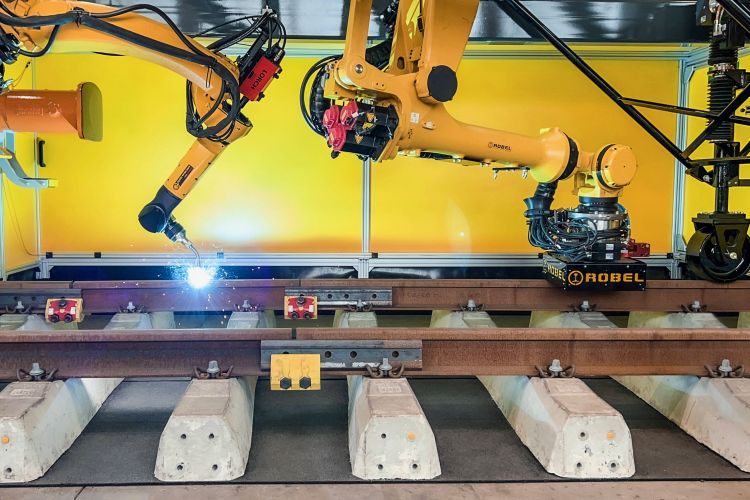

European rail networks have long been facing challenges in terms of maintenance and modernization. However, a promising solution is on the horizon with the emergence of a robotic system capable of repairing rails and switches. Developed by Robel Rail Automation, a Bavarian-based specialist in rail infrastructure maintenance, it heralds a new era of automated railway maintenance.

The system features a rail-traversing wagon equipped with two FANUC robots that efficiently detect and address both internal and external defects. Through fully automatic welding, milling, and grinding processes, the robots conduct precise repairs, streamlining maintenance efforts across European railway networks. Several prototype systems are already operational, with full commercial availability expected within the next two to three years.

Thomas Weis, Head of Development at Robel Rail Automation, emphasizes the growing demand for robot-assisted maintenance systems among customers, particularly for complex repair work on points. As rail network operators face a shortage of skilled workers, the robot system offers a viable solution to tackle the time-consuming and intricate repair tasks.

The Robel Rail Automation System ensures continuous maintenance with the highest levels of safety and resource efficiency. This comprehensive approach helps to detect imperceptible damage and provides customers with digital measurement and process data. With the introduction of this robotic system, European rail networks can look forward to increased efficiency, reduced downtime and improved infrastructure quality.

“There is a lot of need for modernization in both the rail and road networks. Robots can help to complete lengthy maintenance projects more quickly by taking over repetitive work and thus at least partially compensate for the growing labour shortage,” said Ralf Völlinger, General Manager Robotics at FANUC Europe.